ニュースルーム

ニュース、背景、洞察

January 30, 2020

New E-Mobility renews deltaANALYSER

With E-mobility car manufacturers are facing new tasks in development. The latest version of the deltaANALYSER v3 for early stage damage detection is meeting these challenges. We present the most important product innovations to you here.

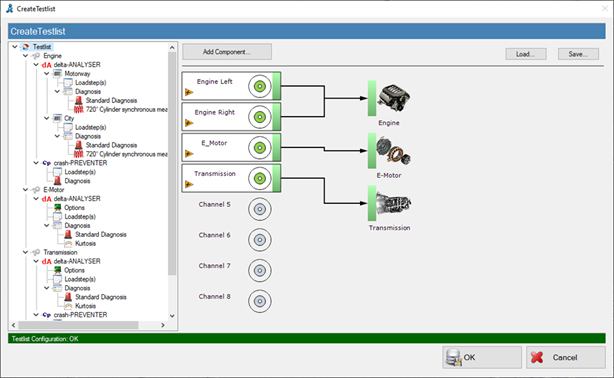

Component based test list configuration

With electric drives, several components of the drive train often have to be checked. This is now possible with the new deltaANALYSER v3. The component based test object configuration allows the user to configure each component individually. Monitoring several components would previously only have been possible with compromises. Because in the previous load step separation, all available status parameters are used and built up as a matrix (e.g. gear information, speed, torque, etc.). It could happen that, for example, in a hybrid application the separation of load steps takes place under irrelevant condition parameters. With the new deltaANALYSER v3, this risk no longer exists, since the test procedure is based on a component based configuration.

Centralized data evaluation via server network (data replication)

Each test run with the deltaANALYSER stores the measurement data in its own database, in which the results can be viewed. Previously, the evaluation and data analysis was done directly on the system or the database was copied to another computer via a storage medium or via the network, so that the evaluation could then done in the office instead of in the test hall.

With the deltaANALYSER v3 the databases can now be replicated to a server simultaneously during the measurement, so that you can conveniently access the each single server database from the office workstation. Without additional manual copying. This increases the comfort of the already comfortable evaluation software considerably.

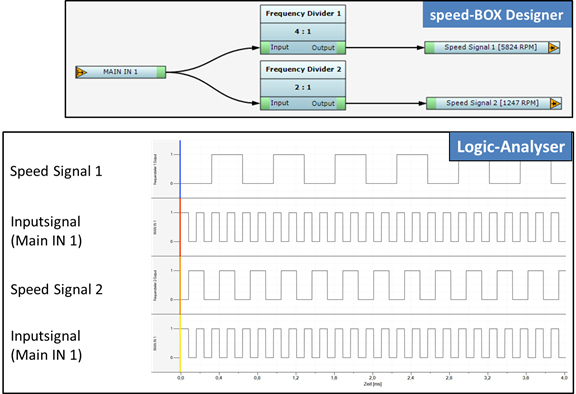

Logic Analyser

The speed signal is a very important input signal for the order analysis. Thanks to the integrated speedBOX, the signal is processed perfectly and can then be adapted in the “speedBOX Designer”, e.g. as a sumsynchronizer, gap filler for crankshaft sensors, TDC determination (0 ° position of the combustion cycle), pulse divider, etc. These adjustments work internally, but so far the result could only be seen as a numerical value. The new “Logic Analyzer” function brings light into the dark and shows now the pulse sequences of each individual step. The adjustment of the pulsed signal can thus be followed exactly. This is a very valuable support when setting up the deltaANALYSER.

New interfaces to the test bench

The interfaces to the new deltaANALYSER v3 have been expanded to include the most commonly used BUS systems today, in particular ProfiNET, Ethercat and Modbus TCP / IP.

Following interfaces are now available:

- Analogue +/- 10 V (8 inputs, 8 outputs)

- Digital 0-24 V (16 inputs, 16 outputs)

- BUS systems (CAN, Profibus, ProfiNET, Ethercat, Modbus)

- Vibration signals 2-8 (sample rate 1 MSPS)

- speedBOX for speed signal processing (4+4 inputs)

- Alarm Relais (potential free)

Automatic low pass filter

Low pass filters have always been used in measurement technology to avoid anti-aliasing effects. However, it is very clear with E-Drive test objects that, on the one hand, a fixed filter cut-off frequency is required due to the frequency inverter. On the other hand, a speed-dependent setting of the filter cut-off frequency is essential in order analyses. Thus a value based on the maximum occurring speed can rarely be the correct one.

With the new deltaANALYSER v3 this problem does not exist any longer. Because it uses a low-pass filter that is always correct for the current speed. This automatically adapts to the correct circumstances. It brings a significant improvement in the damage assignment, since the signal-to-noise ratio in the spectrum is significantly improved.

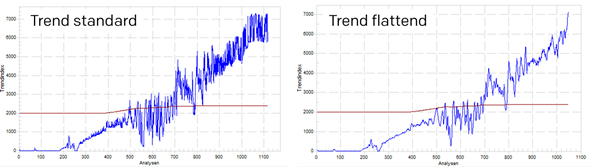

Trend flattening

Everyone knows the phenomenon, especially with dynamic test runs, that the trend index sometimes looks somewhat – let’s say colloquially – “frayed”.

For the deltaANALYSER v3 a new algorithm was developed that flattens the trend index without losing information and sensitivity. This makes the test subject’s damage history even clearer and the onset of damage becomes even more identifiable.

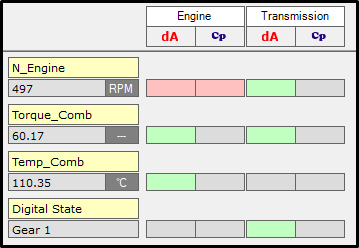

Signal matrix

In line with the new option of component based test list configuration, a signal matrix has been introduced in the monitoring view. Now it is clear which signal is used for which component and whether the signal is in a valid range or not.

Expansion of the display of physical units

Due to some requests from our customers, we have adjusted the display of the y-axis with calibrated units.

The following options are now available:

- Amplitude steps (-)

- Acceleration (g)

- Electric voltage (mV)

- Acceleration (mm/s2)

- Acceleration (m/s2)

- Noise level (dB)

The deltaANALYSER v3 is also available as an update – also for classic combustion engines and transmissions

With the new deltaANALYSER v3 we are responding to the changing requirements in the development of electric drives. “We are extremely grateful for all the feedback from our customers,” says Thomas Satzinger, CTO at Reilhofer, “because this is the only way we can improve our products in a targeted manner. We look forward to experience and optimization requests in the future due to changing requirements. ”

But of course the deltaANALYSER v3 is still used in the development of classic combustion engines and transmissions. Here, too, the innovations offer significant added value.

There is also a corresponding system update for existing systems so that the new functions can be used immediately. Do you want to know more about the new deltaANALYSER v3? Please do not hesitate to get in touch your direct RHF contact or our head office for a personal appointment. See you soon!