Make history.

1989

Foundation of Reilhofer KG

Johannes Reilhofer founded Reilhofer KG in 1989 in Karlsfeld. Originally, the company focused on powertrain analysis by means of structure-borne sound. This approach led to the development of an extensive product family over the years. Prior to establishing Reilhofer KG, Johannes Reilhofer worked in the fields of nuclear power, medicine, automaking, military and mining as the managing director of his measurement company Johne + Reilhofer.

1990

Development of the Stress 2 & Stress 8

The Stress 2 and the Stress 8 were developed to calculate and measure material fatigue. Both of these systems were based on time signal analysis according to the range flow method.

1991

Development of the Crack Logger / Chameleon System

The Crack Logger was the precursor to the first deltaANALYSER and was based on the principle of structure-borne sound. The Chameleon System is a kind of data logger with incorporated algorithm-based analysis, although the customer had to decide what needed to be done. Our experience with these measurement systems laid the foundation for the development of today’s products, which not only present processed data but deliver answers as well.

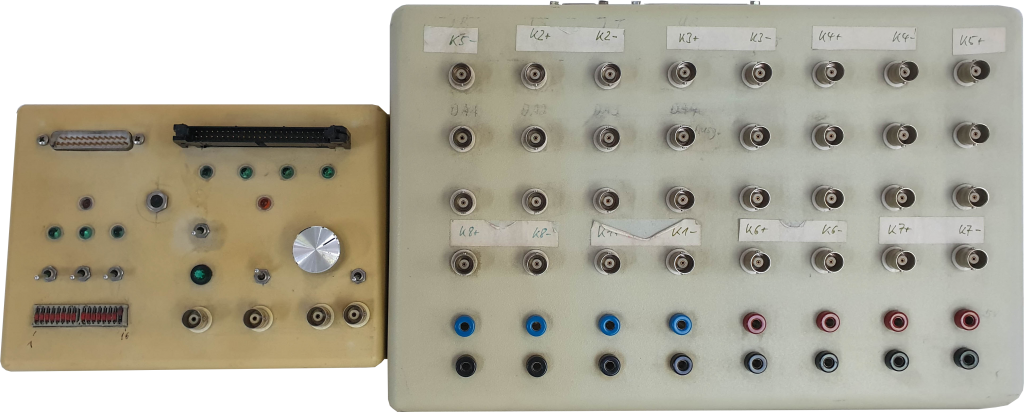

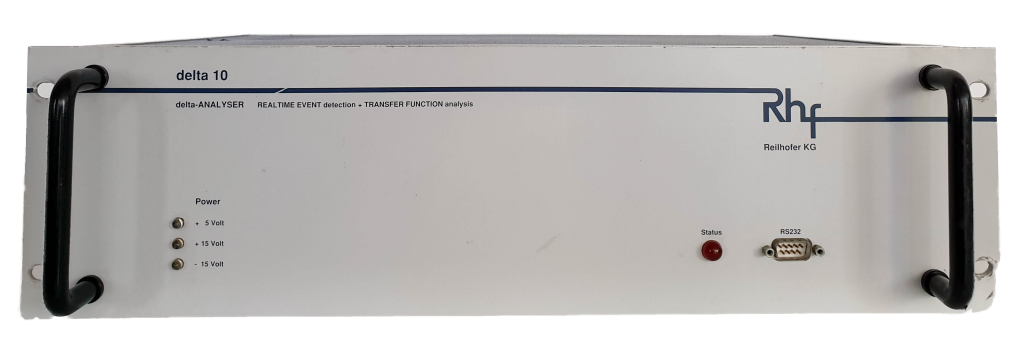

1992

Development of the deltaANALYSER

The first deltaANALYSER was put to the test at the firm STIHL in 1992 after two years of focused development. A shaker was used to excite a structure. Incipient deformation triggered the anticipated alarm. The deltaANALYSER was first used in 1992 for a durability test conducted on a transmission test bed at Volkswagen AG. Initial pitting of the toothing was successfully diagnosed – much earlier than what was usual at the time.

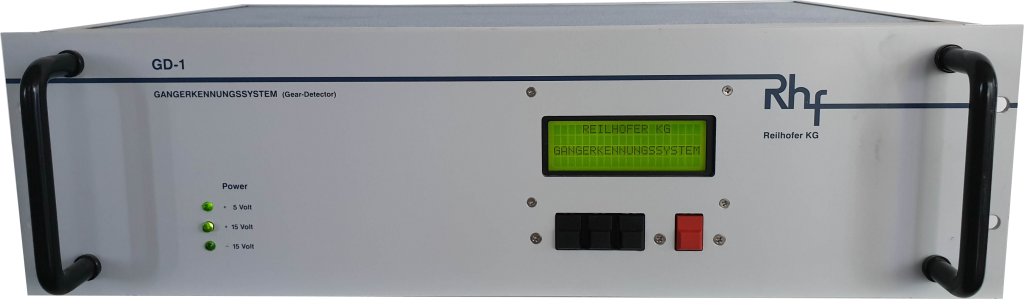

1993

Development of the Gear Detection

Porsche requested the inclusion of several parameters in the first deltaANALYSER. This led to our release of the Gear Detection System in 1993.

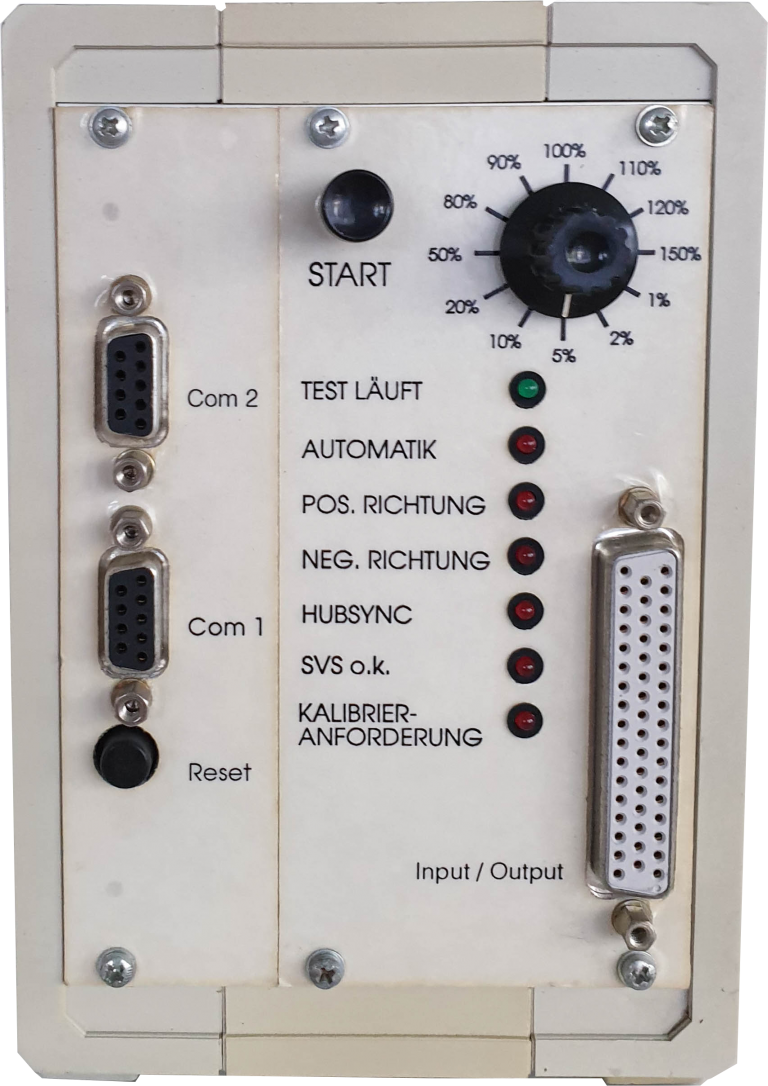

1994

Grinding Burn Prevention

Reilhofer KG developed a grinding burn prevention system for ZF in 1994. Toothed wheels may experience local overheating during the grinding process, rendering them useless. The Grinding Burn Prevention System (SVS) stops this from happening and enables a 30% increase in throughput at no risk. Reilhofer KG created this product exclusively for ZF.

1995

Development of the turbo-CONTROL

Kühnle, Kopp & Kausch (later: Borg Warner) approached Reilhofer KG in 1995 with the wish to measure the imbalance of turbochargers. Our turbo-CONTROL was the world’s first diagnosis and balancing system that completed a measurement during the fast initial ramp-up, delivering balance correction data for the compressor wheel in two planes.

1997

Development of the GEAR SHIFT check

Collaborating closely with ZF, Reilhofer KG developed the GEAR SHIFT check in 1997 for the simple and effective monitoring of switching and synchronisation processes. It diagnoses the point at which switching operations deviate from their expected behaviour and provides information on error frequencies.

1998

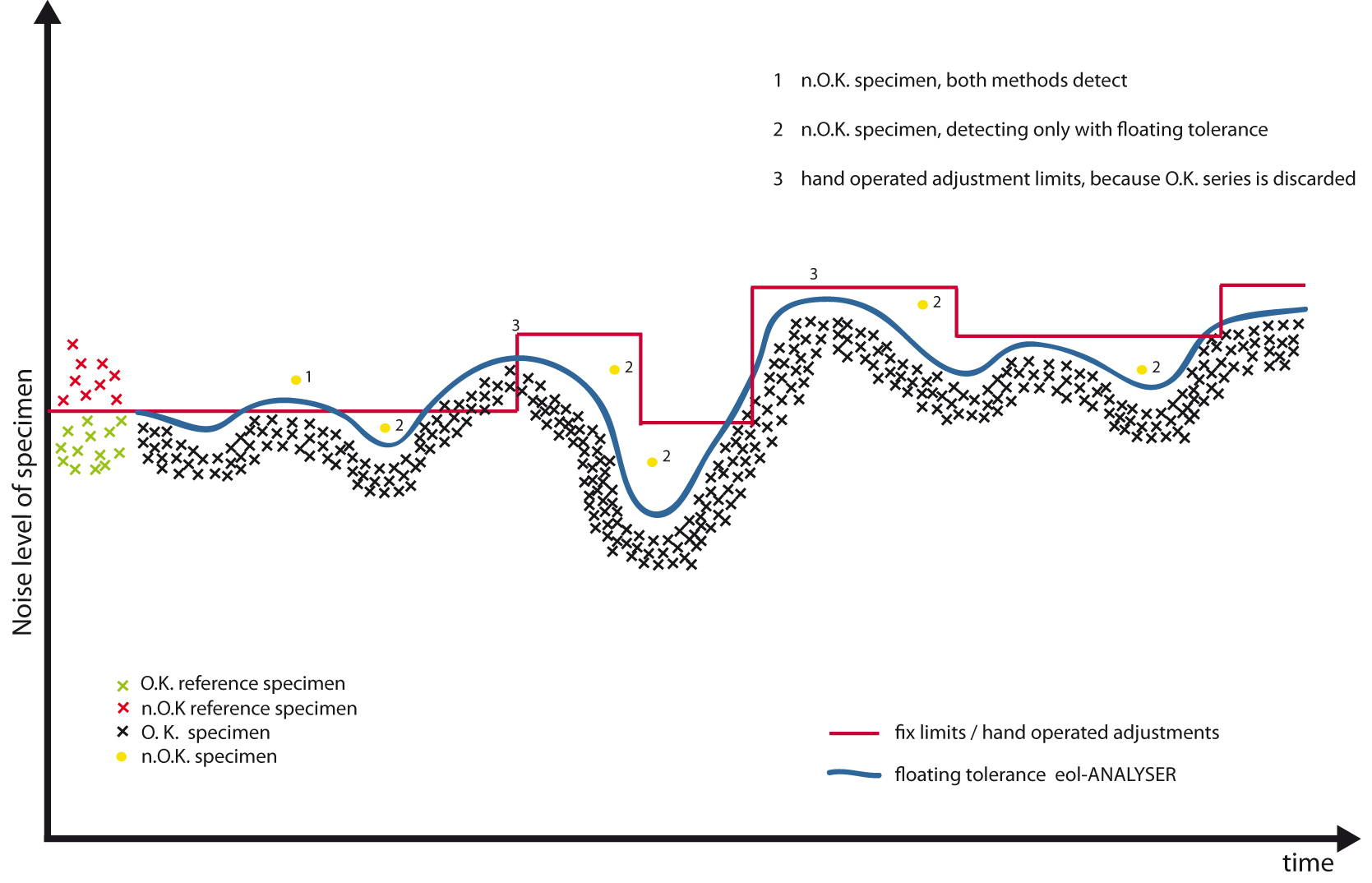

Development of the eolANALYSER

The eolANALYSER was developed in 1998 as an additional diagnosis system and was specifically designed for the testing of ongoing production for combustion engines, transmission units for cars and lorries, as well as stationary systems. The end-of-line system has self-learning capabilities. This function is revolutionary, as it enables 24/7 operation without the need for continuous human supervision to make the technical adjustments.

1999

Relocation of Company Headquarters

The premises on Frühlingsplatz in Karlsfeld were soon bursting at the seams, given the steadily expanding product range and a growing team. The headquarters and all departments moved to their new home at “An der Steinernen Brücke” in Karlsfeld. This gave us an ideal production and working environment that was perfectly suited to our needs. But we remained true to our roots in Karlsfeld near Munich.

1999

Breathing Collective for the eolANALYSER

Over time, the aggregate number of production-related influences will exceed the tolerances of fixed limits. This prompted Reilhofer KG to develop the ‘breathing collective’ that works with production tolerances. Outliers, meaning production faults, go beyond this breathing tolerance. To ensure that the production limits do not experience drift as time passes, the eol software includes an absolute value that is calculated based on production fluctuation over a longer period.

1999

Development of the crash-PREVENTER

In 1999, Volkswagen AG requested the integration of an additional break shutdown feature for the existing deltaANALYSER. It needed to work autonomously. This prompted Reilhofer KG to develop the crash-PREVENTER.

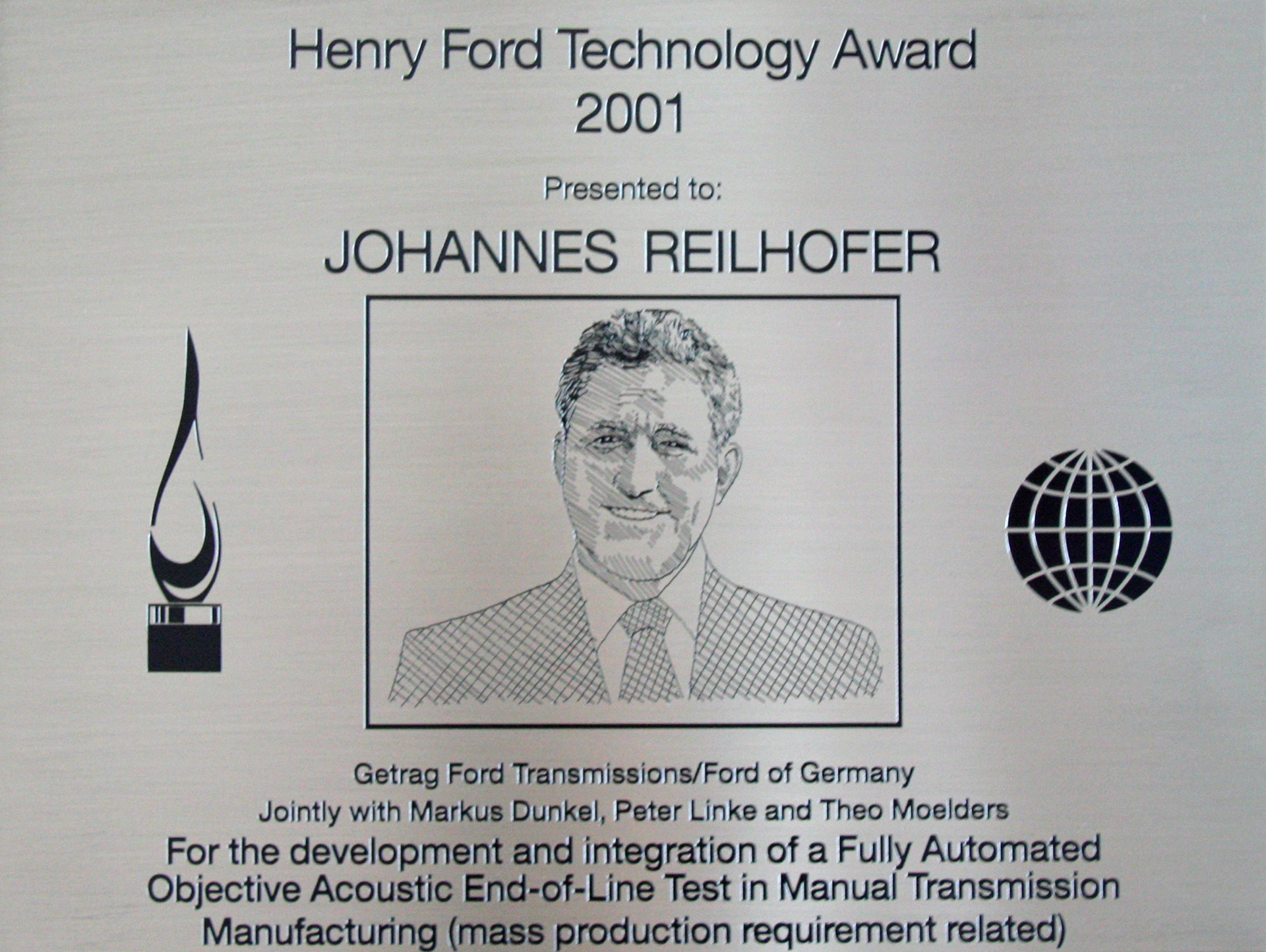

2001

HENRY FORD AWARD

We received the 2001 Henry Ford Award in the United States for our ‘breathing collective’ and the autonomous determination of reference values. Prior to this, Ford had used the eolANALYSER to test over 250,000 transmission units.

2002

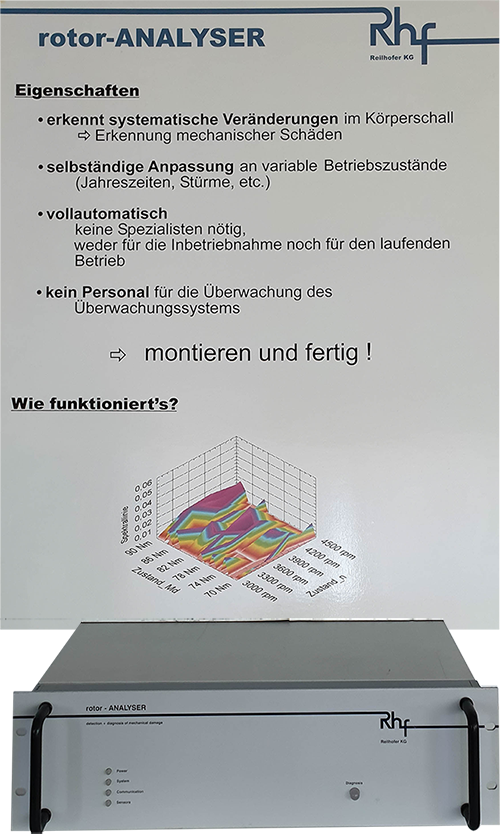

Development of the rotor-ANALYSER

The rotor-Analyser was developed to protect wind turbines. It is able to include various external operating conditions like wind, temperature and others in its damage analysis so as to prevent false alarms.

2003

Development of the acoustic-LASER

The acoustic laser project was launched in 2003. We had noticed in tests that the laser vibrometers used at the time did not work for non-contact measurements on standard surfaces. The acoustic-Laser was completed after 4 years of development as the first non-contact sensor that works on any measurement surface. The trickiest requirement: the system needed to measure vibration velocities of less than 0.1 mm/sec. This is a truly daunting task if one considers that the speed of sound at 20 °C is 340 m/sec. But we rose to every challenge with the acoustic-LASER.

2003

Inaugural Reilhofer Technology Day in Germany

As our customer base grew, we realised that users of our diagnosis systems were keen to discuss possible uses and personal experience in more detail. This prompted us to organise the Reilhofer Technology Day conference. Since then, interested customers and partners from the German-speaking markets have met every 2 years to share their views.

2008

Opening of the Subsidiary in Shanghai/China

Our first diagnosis system was sold to China in 2008. We recognised the potential of this market and set up a 100% subsidiary in China, which opened its doors in Shanghai in 2008. Numerous prestigious Chinese companies have joined our customer base since then.

2008

Development of the deltaANALYSER mobile

We conducted our first tests with a deltaANALYSER mobile in 2008. deltaANALYSER mobile is a highly useful tool if the transmission starts ‘rattling’ thanks to its easy in-vehicle application and quick analysis findings.

2009

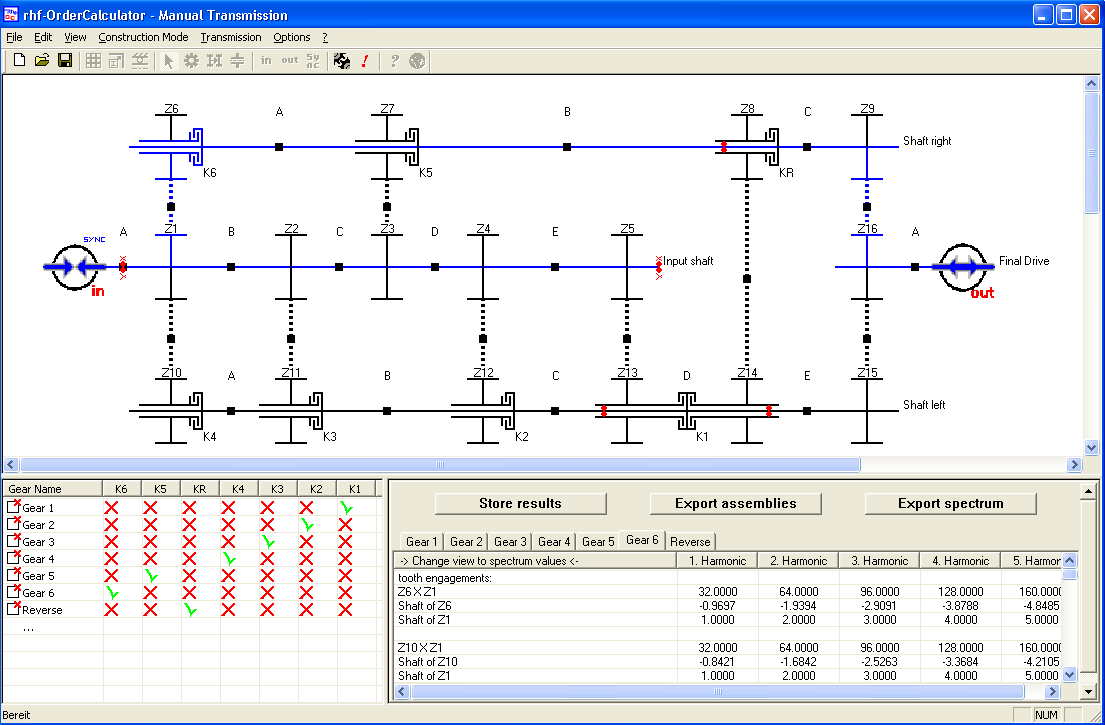

ROC – Reilhofer Order Calculator

The program to calculate the harmonic orders created by specimens was completed. The ROC was developed in 2009. Initially, it only considered the transmission. But now it can also calculate the engine and e-drive. Calculations can be produced for the entire powertrain as well. We attached particular importance to ease of use.

2010

Opening of the French Office

Several years of successful operation on the French market encouraged us to open our own permanent establishment in the country. Thanks to this location, we can now to guarantee fast and efficient customer support in this field.

2012

Relocation to New Headquarters

A move to new headquarters in larger premises was necessitated by our expanding portfolio and growing workforce. The building on Zugspitzstraße – still in Karlsfeld near Munich – offered perfect facilities.

2013

Vogel Industrie Verlag Award

We received the 2013 Vogel Industrie Verlag Award in China for the valuable support provided to the Chinese automaking industry. Among the main reasons for the distinction was the deltaANALYSER system, which for a long time had delivered excellent and reliable insight to Chinese automotive manufacturers on the development test beds for transmissions and engines.

2014

Foundation of H-Reilhofer in Shanghai

The Chinese company H-Reilhofer was established in 2014 in Shanghai as a joint venture. The company is specialised in the development and manufacture of customised test beds for the automotive industry (AT, MT, DCT, CVT, e-drives etc.).

2014

First Reilhofer Technology Day in the United States

The North American market became increasingly important to us over time. Hence, organising a regular Reilhofer Technology Day in the USA seemed like a sensible option. The event was warmly received and has now become an annual gathering of industry customers and partners who meet at our expert conference in Detroit to discuss acoustic measurement technology, NVH, early stage damage detection and quality assurance.

2015

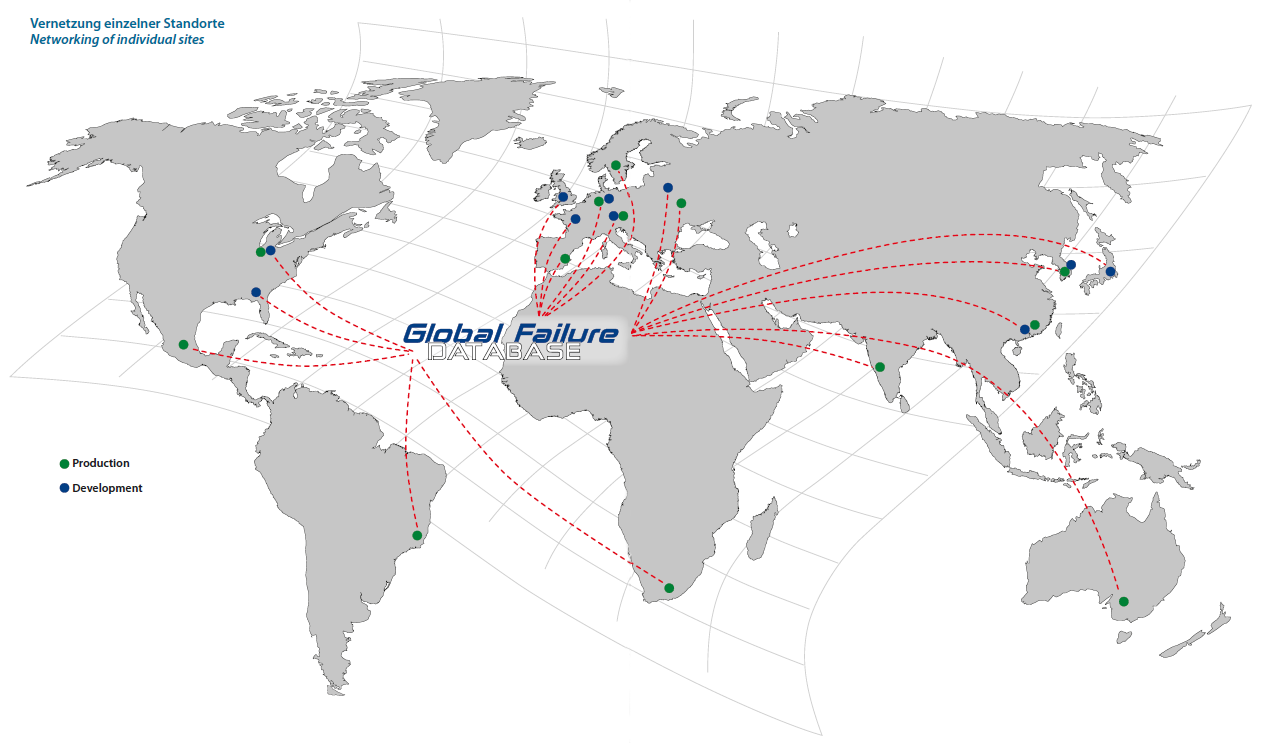

Development of the Global Failure Database

The Global Failure Database was programmed to present the damage and faults detected in a neat and orderly form, as well as to enable analysis. It allows the clearly structured evaluation of data obtained with the deltaANALYSER and the eolANALYSER across locations.

2016

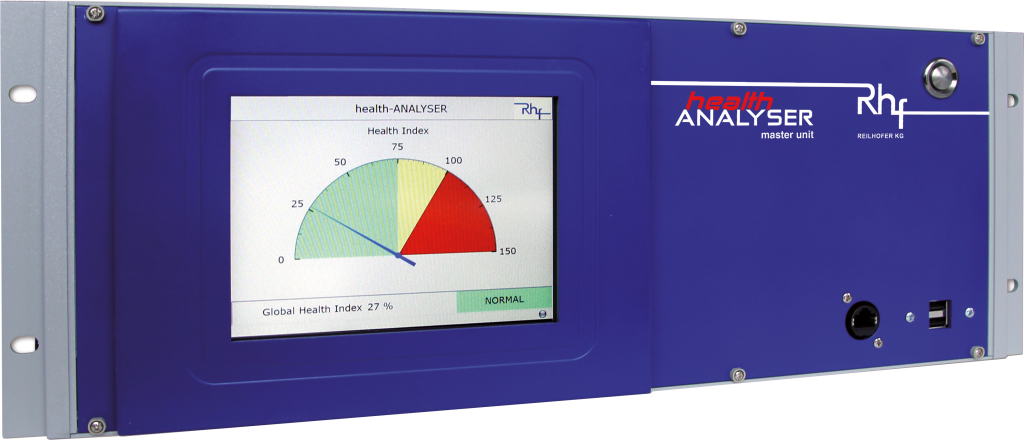

Development of the health-ANALYSER

The health-ANALYSER was developed to provide central monitoring of industrial machinery. It is the precursor to a future measurement device that will include Industry 4.0 features.

2017

ISO 9001:2015 Certification

Our efficient quality management received official ISO 9001:2015 certification for the first time in 2017. We continue to adhere to our principle of ensuring well-designed workflows that contribute significantly to maintaining the quality of our products and services.

2018

Opening of the Italian Office

We founded a permanent establishment in Italy in 2017 to meet the growing demand for our products on the Italian market. It means we are now able to provide direct support in the local language.

2018

First Reilhofer Technology Day in Italy

An inaugural Reilhofer Technology Day was the next logical step once the Italian office was up and running. Industry representatives, customers and partners met for the first time in 2018 to share their views on the opportunities for acoustic measurement technology in connection with electric and conventional drives.

2019

First Reilhofer Technology Day in China

The successful series of technical conferences, the Reilhofer Technology Days, has now spread to China as well. The first Asian event was held in 2019. Others are certain to follow due to the warm reception and the strong interest in this industry conference.

2019

New managing director

After a total of 50 years as Managing Director, Johannes Reilhofer is now officially stepping down as Managing Director and taking a well-deserved break from day-to-day business. The job of Managing Director has been handed over to Stefan Salvermoser, who has been responsible for the commercial processes at Reilhofer KG for many years. Mr. Reilhofer remains the owner and will of course be available to answer any questions colleagues may have.

2020

Establishment of the office in the USA

After many years of representing TED on the American market, we have decided to staff our own employees in the USA. The direct support with our local employees now makes it possible to provide fast and effective customer support.

2021

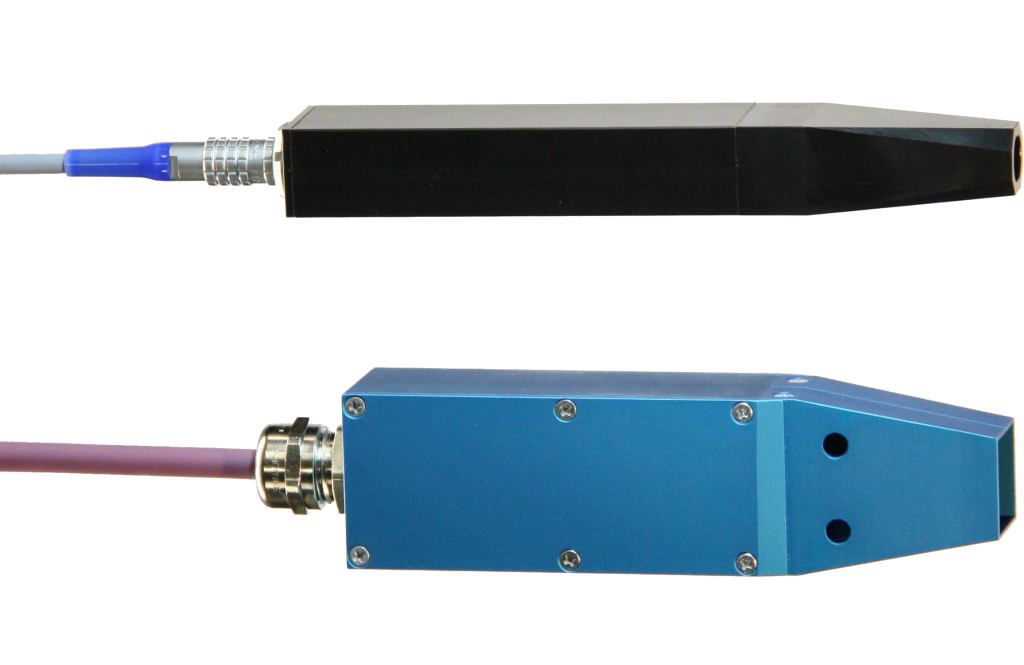

Pressing Device Sensor

Development of the pressing device sensor. We have succeeded in realizing an easy-to-handle and durable solution for measurement directly on the housing. Small, compact and a stable frequency response are the decisive factors.

2023

New domicile

The increased number of deliveries and the growing number of employees make the next move to larger premises necessary. We move out of Karlsfeld for the first time in 34 years. Our new domicile is now 10 km away in Hans-Böckler Straße in Dachau.

2024

W-Ibeda test centre for electric drives

Opening of the W-Ibeda test center for electric drives in Bergkirchen near Munich. With 14 e-drive test benches and battery simulation test benches for endurance tests, functional tests, performance tests, road tests and component tests, the test center is well positioned for the future of mobility.

2025

NextGen

Launch of a new 32-bit hardware platform to ensure maximum precision for all measurement requirements. This makes Reilhofer KG one of the first in the structure-borne sound analysis segment to introduce this technology. One hardware for all applications (development and production).