End of errors.

Quality assurance for the latest generation of powertrains.

Frequently asked questions

Acoustic final quality control - crucial for reliable products

In modern production - especially in the automotive industry, mechanical engineering and electrical engineering - acoustic end-of-line testing is becoming increasingly important. Noises often reveal at an early stage what conventional testing methods only discover later: production errors, component deviations or assembly defects.

This is why end-of-line testing is supplemented by acoustic evaluation using structure-borne sound analysis. This takes on two central tasks:

1. Ensuring the quality of the installed mechanical components

2. Monitoring the volume and acoustic behavior of the test specimen

In this way, not only the function, but also the quality and noise development are reliably evaluated - for a comprehensive test concept.

Why acoustic final inspection is indispensable

Every technical system generates characteristic vibrations and noises. If these are analyzed, mechanical irregularities, contact problems or bearing damage can be detected immediately - even before they lead to failures or complaints.

By using structure-borne sound sensors and intelligent signal processing, faults can be detected that are not noticeable from a purely visual or electrical perspective.

Whether electric motors, actuators, pumps, combustion engines or transmission components: The acoustic final inspection can be flexibly adapted to different products and test benches. Our system detects even the smallest deviations in vibration behavior - fully automatically, in real time and with high reproducibility.

Various sensors are available for measuring structure-borne sound.

The most common are:

- firmly screwed sensors

- pressed-on sensors

- Non-contact sensors

- Airborne sound sensors

IEPE/ICP sensors have established themselves among the bolted and pressed-on sensors.

The acceleration sensor can either be screwed directly to the static side of the test stand or to the hydraulic clamps.

An adjustment unit is required for the pressed-on sensors. Reilhofer KG has developed a special pressing device sensor for this application. It has been optimized for an ideal frequency response. The sensor is particularly durable, easy to calibrate and easy to maintain.

Alternatively, non-contact measuring methods such as laser vibrometers or microphones can also be used.

Microphones, on the other hand, are only suitable for quality assurance to a limited extent, as they can be strongly influenced by ambient noise.

If infeed units and non-contact measurement are not an option, it is still possible to integrate a sensor directly onto the shaft. This torsional acceleration sensor is also suitable for detecting tooth flank errors.

One or two sensors are usually sufficient for reliable structure-borne noise analysis on vehicle components. These enable a quick and precise assessment of components as part of acoustic quality assurance.

For complex structures such as engines, gearboxes or chassis components, however, the use of up to eight structure-borne sound sensors may be necessary - especially for the detection and differentiation of hidden noise sources, resonance effects or structure-borne noise.

In many cases, a multi-axis NVH measurement is recommended to detect certain acoustic anomalies. This makes it possible to detect sound phenomena that are only perceptible in specific directions.

We will be happy to support you in selecting the optimum number and placement of sensors - optimized for your specific testing task, component geometry and production environment.

Fixed limit values are perfect for reliably detecting defined noise emissions, for example during gear mesh or to limit the speed level. However, not all errors can be predefined in advance. That's why we use automatically learning, adaptive limits that adjust dynamically to daily production.

These limits are closely based on the current production data and continue to adapt. To prevent them from "derailing" in an uncontrolled manner, we define an absolute upper limit based on a long-term database - for example, the last six months. It takes into account typical fluctuations such as tool changes, material batches or variations in supplied parts.

The result: a robust, adaptive system that reliably detects both known and unexpected errors without losing control - for greater safety and efficiency in your production.

Order analysis is the most powerful tool for speed-independent structure-borne noise measurements. While the speed changes, the orders in the spectrum remain in their fixed position - only the amplitudes (e.g. in m/s², g or mV) change. This allows narrow tolerances to be defined, with which even the smallest deviations in acoustic behavior can be reliably detected - for precise diagnostics and fault detection.

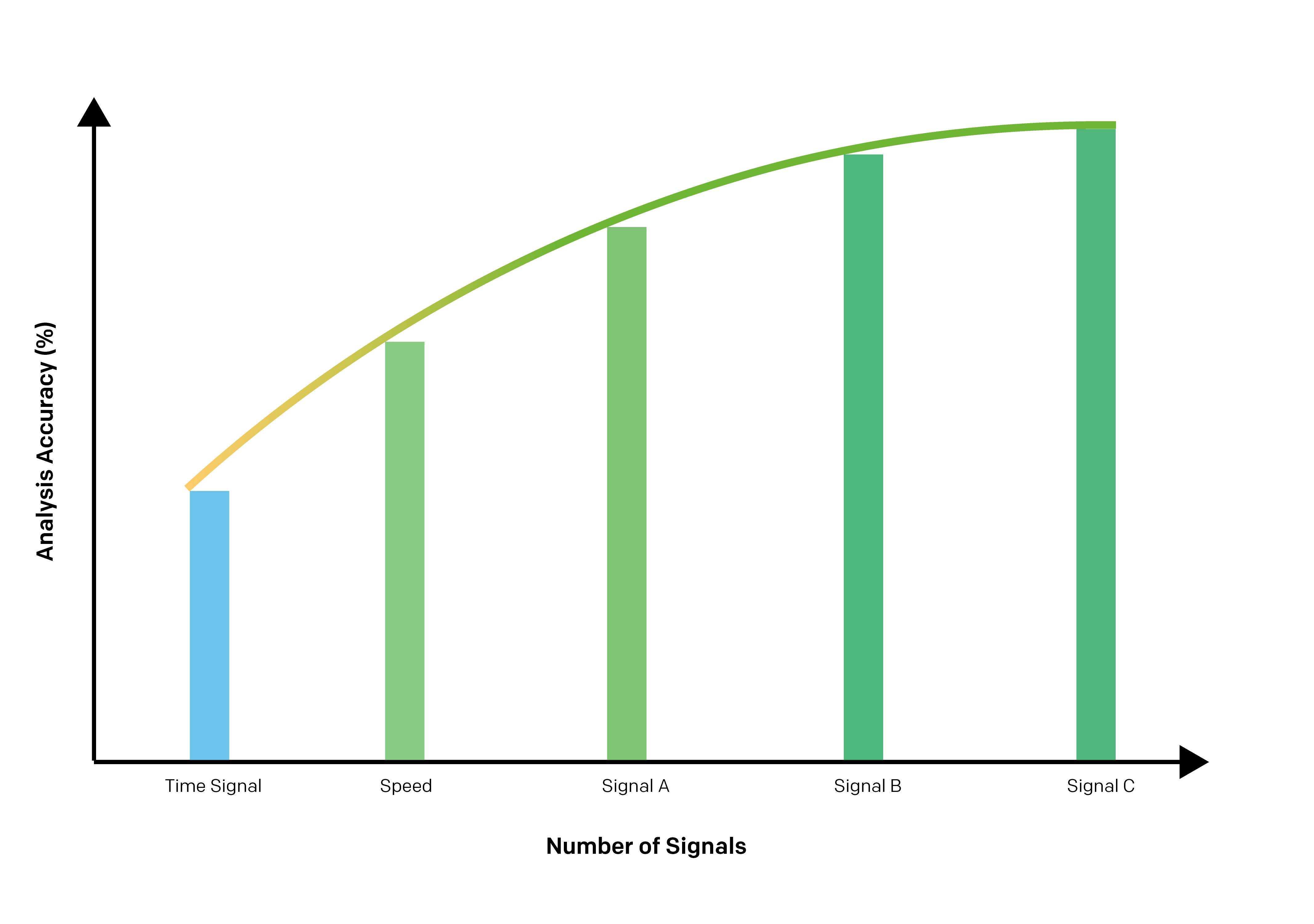

Order analysis is a highly effective tool, but only one component of a holistic quality assurance system.

1. Different faults - different signatures:

Mechanical, electrical or acoustic faults show up differently. Some methods are particularly good at detecting bearing faults, others are more effective in the case of imbalances or gear mesh problems.

2. Robustness through redundancy:

Multiple methods increase the reliability of fault detection and minimize the risk of false positives and false negatives.

3. Functional adaptation to the test specimen:

What works for a combustion engine is often irrelevant for an electric motor. Application-specific procedures are therefore used.

4. Combined evaluation:

The eol-ANALYSER uses over 25 procedures to provide a comprehensive picture - comparable to a doctor making an accurate diagnosis through a variety of tests.

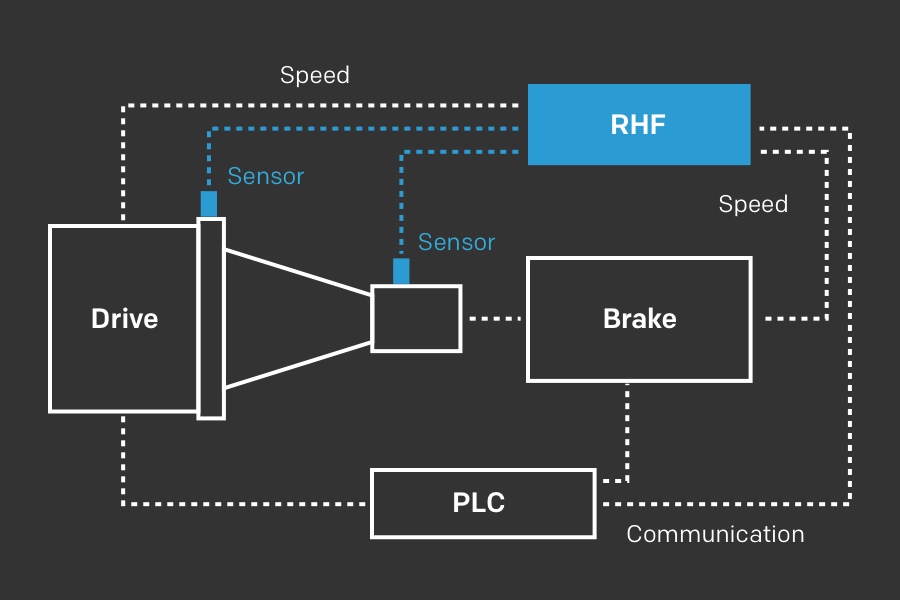

Precise speed detection is the basis for accurate and reliable order analysis. The speedBOX is therefore an indispensable component of the eolANALYSER. It reliably converts a wide variety of input signals into a clean TTL signal - regardless of the signal form. Thanks to its galvanic isolation from the test bench signal, it guarantees maximum signal quality and safety. The flexibly configurable speedBOX supports a wide range of applications - from all-wheel drives to individual motorcycles. An additional output enables the control of further systems, such as the test bench or additional measurement technology.

The test steps adapt precisely to the specific measurement requirements of the test specimen. When driving through a ramp, for example, it can be divided into a single test step or into up to five segments - each with individual test procedures. The test steps are defined flexibly using various signals, such as digital bitcode or speed. This ensures maximum flexibility and precise control of your tests.

The raw data is saved in the standardized ASAM-ATFX format. This means they can be used in external applications without any problems and can be easily processed for subsequent analyses - for maximum flexibility and efficient data utilization.

The integrated what-if analysis tool in the evaluation allows previously tested test specimens to be subsequently evaluated with new limit values. This allows you to identify potentially better settings - without having to repeat tests on the test bench. This allows you to identify optimization potential and improve your processes efficiently and in a resource-saving manner.

The eol-ANALYSER evaluation provides you with a clear graphic overview of your production stability. This allows you to identify potential deviations at an early stage and initiate countermeasures in good time - even before rejects occur. For proactive quality assurance and greater efficiency.

The calculated order files for each component type can be seamlessly integrated into the eol-ANALYSER. Conspicuous orders in the test step can be quickly and reliably evaluated using the ROC calculations so that affected components can be quickly identified. Even users without special NVH knowledge (noise, vibration, harshness) are able to carry out well-founded diagnoses. The method can be used both offline in the evaluation and fully automatically and in real time directly on the test bench - the tester receives the results live on the screen.

more about ROC

With the eol-ANALYSER, various analysis methods can be flexibly combined to precisely define specific fault patterns. The individually created fault descriptions are displayed in plain text both on the test bench and in the evaluations. These named faults also appear in the statistical reports so that it is immediately clear which faults occur most frequently. These valuable findings form the basis for targeted measures for continuous quality improvement.

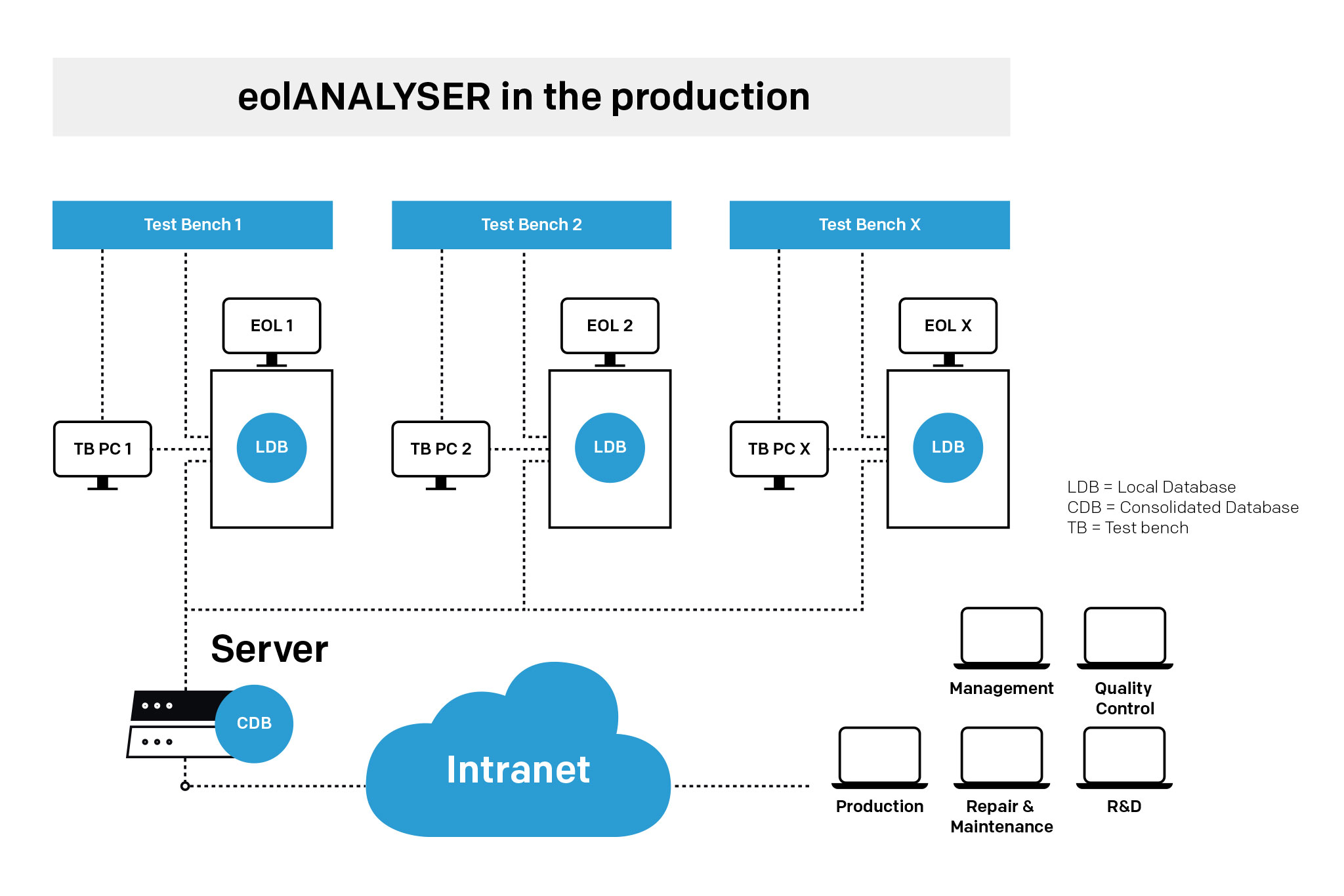

All data recorded during the test run is stored in an SQL database. Data can be stored flexibly over longer periods of time, depending on requirements and application.

The integrated evaluation software enables a comprehensive analysis of all test steps, including the procedures used and the results achieved. Various statistical functions are available - including, for example, the overall development of the quality indicators over defined periods of time.

Specific analyses, such as the amplitude level of individual orders across a large number of test specimens, are also possible. This allows the production quality of individual gears to be specifically tracked over time.

For management, the integrated reporting tool offers an efficient way of summarizing key quality indicators in a clear report with just a few clicks - ideal for quick and well-founded decisions.

This offers the decisive advantage that internal experts can assist with the analysis without the need for time-consuming and costly travel. This increases efficiency and at the same time significantly reduces the response time for quality issues.

Best advice.

Our brochure for download

Download the eolANALYSER brochure and find out everything in detail.

PDF DownloadCertified quality: ISO 9001

Assured quality through optimal process management in accordance with ISO 9001:2015 certification. Your advantage: perfect product and service quality right from the start.

Standardised export formats: ASAM Member