Anticipation.

Early damage detection for the digital age. Always on.

Frequently asked questions

Despite the latest computer animations and 3D printing technologies, mechanical testing of designed components remains essential. Only through real tests can you detect weak points at an early stage and ensure the quality of your production. Our comprehensive test run identifies potential risks and enables continuous optimization - for reliable designs and maximum safety

With our early damage detection, you can identify damage immediately - only the affected component needs to be replaced, while the remaining parts remain undamaged. This prevents consequential or total damage and allows you to keep an eye on the source of the problem. For you, this means: continued use of undamaged components, considerable time and cost savings as well as safe and efficient operation.

When testing e-drives, motors, gearboxes or individual components, often only the most important parameters such as speed, torque or pressure are monitored to ensure that the test object is functioning correctly. However, in order to detect wear damage, it is necessary to monitor structure-borne noise. Simply monitoring the total structure-borne noise is not sufficient, as the test specimen generates noise even without wear.

The delta-ANALYSER distinguishes between normal operating noise and damage-related signals at an early stage and detects weak points in good time. With precise diagnostics, it shows exactly which component is beginning to suffer damage.

The most common method for measuring structure-borne sound is to mount accelerometers directly on the test specimen, ideally screwed on for the best results. Alternatively, they can be mounted magnetically or glued - however, we recommend that you avoid pressing or pressing on with springs. For a non-contact solution, measurement with a laser vibrometer is also possible, but as this is more expensive, it is rarely used for endurance runners. Microphones, on the other hand, are hardly suitable for early damage detection, but are sometimes used to check audibility outside the test bench.

Depending on the measurement situation, up to 12 structure-borne sound sensors can be used. As a rule, one sensor is used per test specimen. For a complete powertrain consisting of combustion engine, transmission, electric motor, transfer case and rear axle, for example, five sensors are required. If the combustion engine has more than five cylinders, additional sensors can be attached to the engine.

When testing the entire powertrain, individual components can be specifically evaluated. Our monitoring function can be individually adapted to each component - for efficient, precise and comprehensive monitoring that does not miss any details.

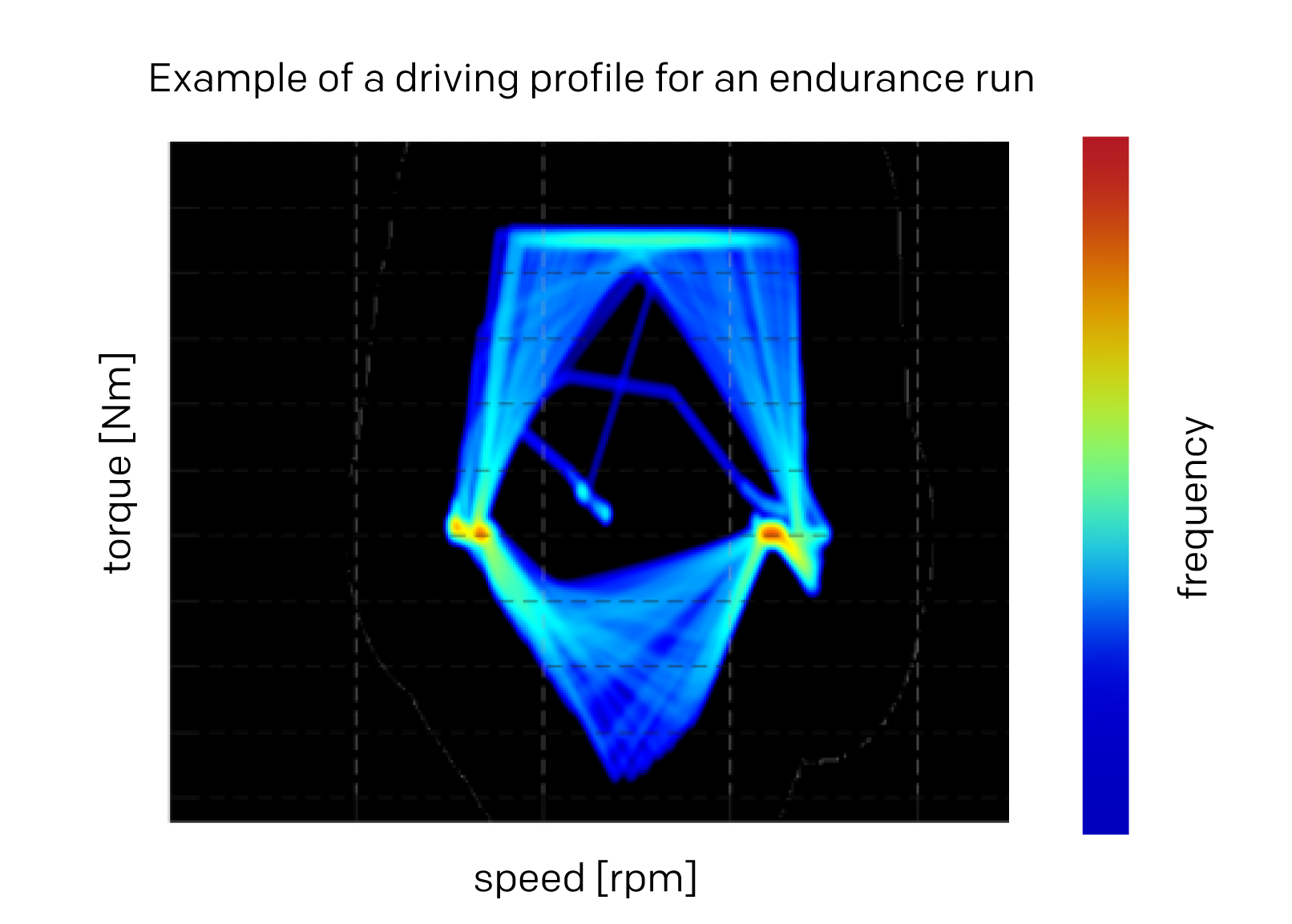

Order analysis is the best tool for a speed-independent structure-borne sound analysis. When the speed changes, the orders remain in the same place, only the amplitude levels (e.g. m/s², g, mV or dB) change. This allows narrow tolerances to be set so that even the smallest changes become visible.

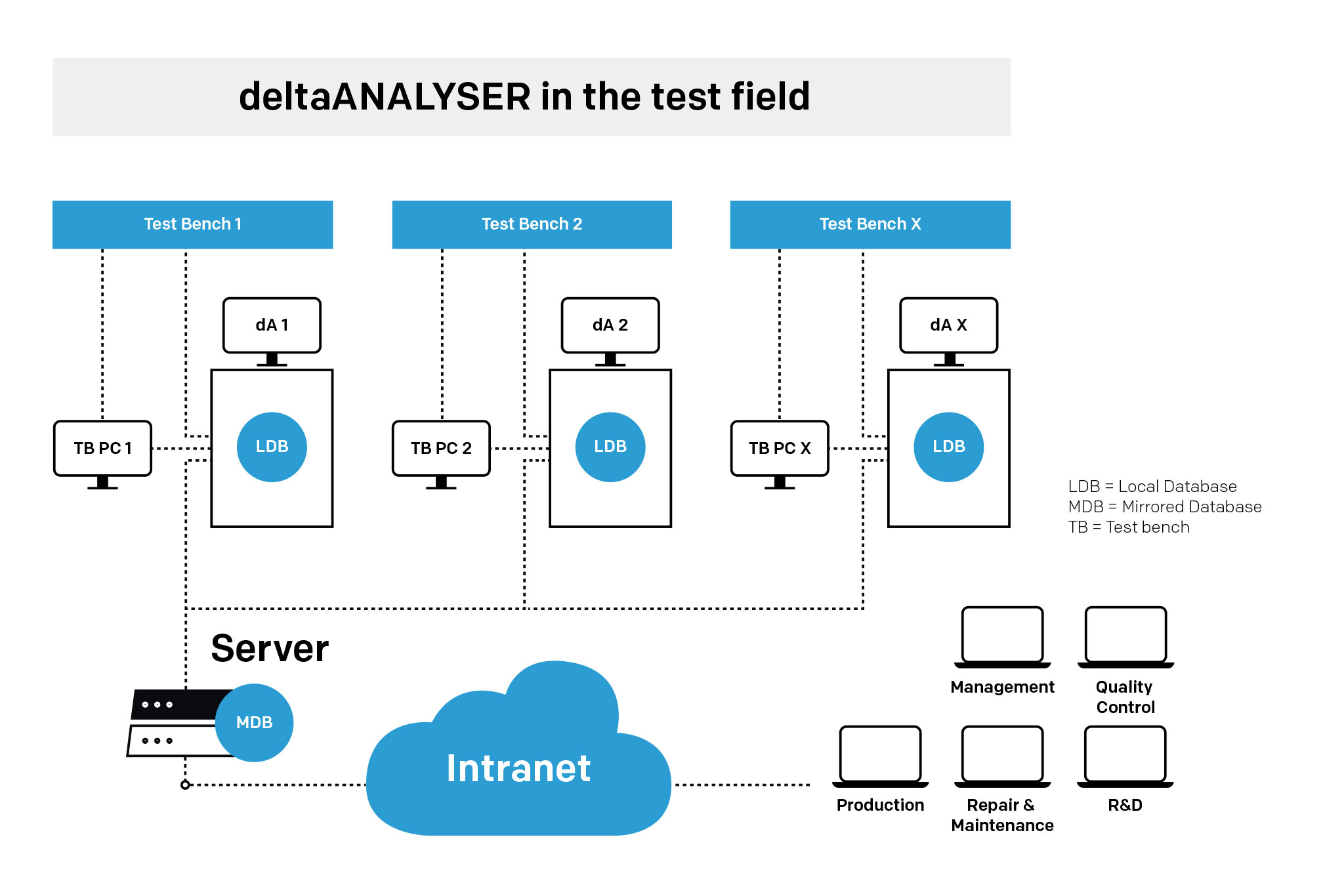

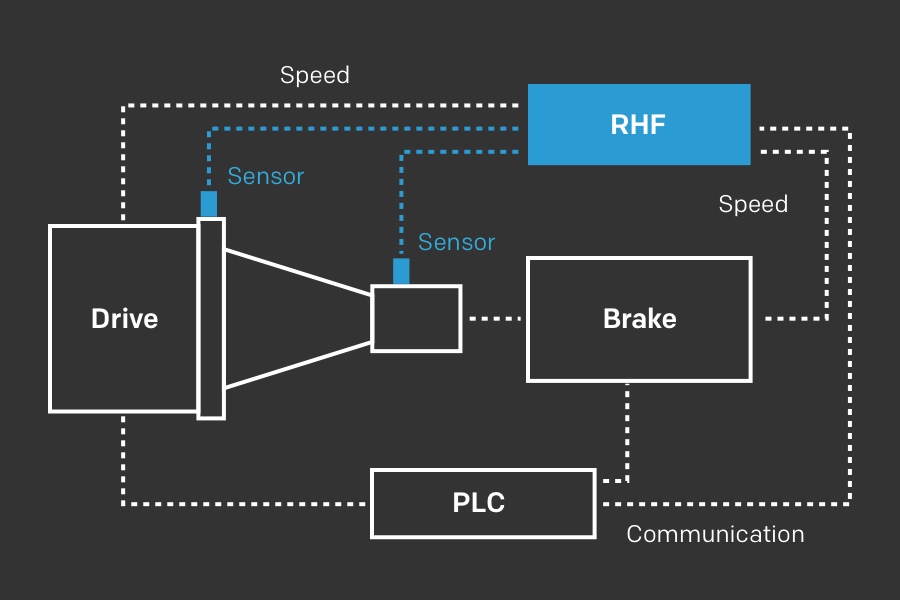

A precise speed is the basis for reliable and accurate order analysis. The speedCard with four speed inputs is therefore an integral part of the delta-ANALYSER. It converts a wide variety of signal forms into a clean TTL signal and is electrically isolated from the test bench signals to prevent interference. The delta-ANALYSER offers flexible configuration options for a wide range of applications - from all-wheel drives to combustion engines. It can also be extended to up to eight speed signals to cover complete hybrid drive systems - for the highest possible accuracy in every application.

Various methods are required to detect all faults at an early stage. Order analysis is only one part of comprehensive early damage detection. The delta-ANALYSER integrates nine different structure-borne sound methods that are specially optimized for the respective components. Different methods are sometimes used for e-drives, e-motors or gearboxes than for combustion engines. For example, a 720° analysis only makes sense for engines - this is how we ensure precise and accurate fault diagnosis in every application.

During the endurance test, changes to the test specimen can be detected in the order range. Reilhofer KG has developed the unique Reilhofer Order Calculator (ROC) for fast and precise allocation of components. With this program, test specimens can be reproduced quickly and schematically. The ROC creates all conceivable powertrains in the shortest possible time and calculates the orders generated by structure-borne noise. It covers classic gearboxes and motors as well as e-drives and complete drive systems - for efficient fault analysis

more about ROC

The delta-ANALYSER automatically generates detailed reports during the test run that include all important changes and component identifications. All relevant KPIs are taken into account - without exceeding any limit values. Cyclical reports can also be generated automatically, for example daily or after certain operating hours. In the event of an alarm, automatic report generation ensures that those responsible are notified immediately - for proactive monitoring and rapid response.

In addition to order analysis, we use additional time signal methods to ensure a rapid shutdown in an emergency. These specialized methods monitor the structure-borne sound for spontaneous fractures or cracks, for example in the case of timing chain cracks. If immediate danger is detected, a shutdown signal is immediately sent to the test bench - for maximum safety during the test.

Best advice.

Our brochure for download

Download the deltaANALYSER brochure and find out everything in detail.

PDF DownloadCertified quality: ISO 9001

Assured quality through optimal process management in accordance with ISO 9001:2015 certification. Your advantage: perfect product and service quality right from the start.

Standardised export formats: ASAM Member