ニュースルーム

ニュース、背景、洞察

Juni 30, 2020

The deltaANALYSER runs along the “Via Emilia” in Italy … for durability tests

What once started with a single deltaANALYSER as a “fancy tool” in northern Italy for Early Stage Damage Detection became the beginning of a product journey along the historic “Via Emilia” and the automobile companies established there.

Engines are the heart of every vehicle. And in the heart of northern Italy is the “Motor Valley”, a strong economic region in which world-famous vehicles are manufactured. Here on “Via Emilia” you will find some of the most renowned manufacturers of high-performance engines in the world. Many years ago, a company in the Bologna region invested in the development of a new, powerful engine. They heard about the “fancy tool” of an acoustic diagnostic system for Early Stage Damage Detection in development that comes from Germany and bought it. The first deltaANALYSER thus moved to the region. Many years and many installed deltaANALYSER later, Reilhofer KG is now present with its own office in the Northern Italy region, not far from Ravenna and Lugo di Romagna, close to the Motor Valley.

“We take care of our customers in Italy along the” Via Emilia “. We offer our full support on site and in the local language. Our customers receive the extensive service: from integration in test benches, through setting and test monitoring to training for an optimized use of the deltaANALYSER. Our solutions are comprehensive support for Early Stage Damage Detection and hardware and software tailored to the respective application, including specialist support.”

Stefano Geminiani, Sales and Consulting, Reilhofer KG Italy

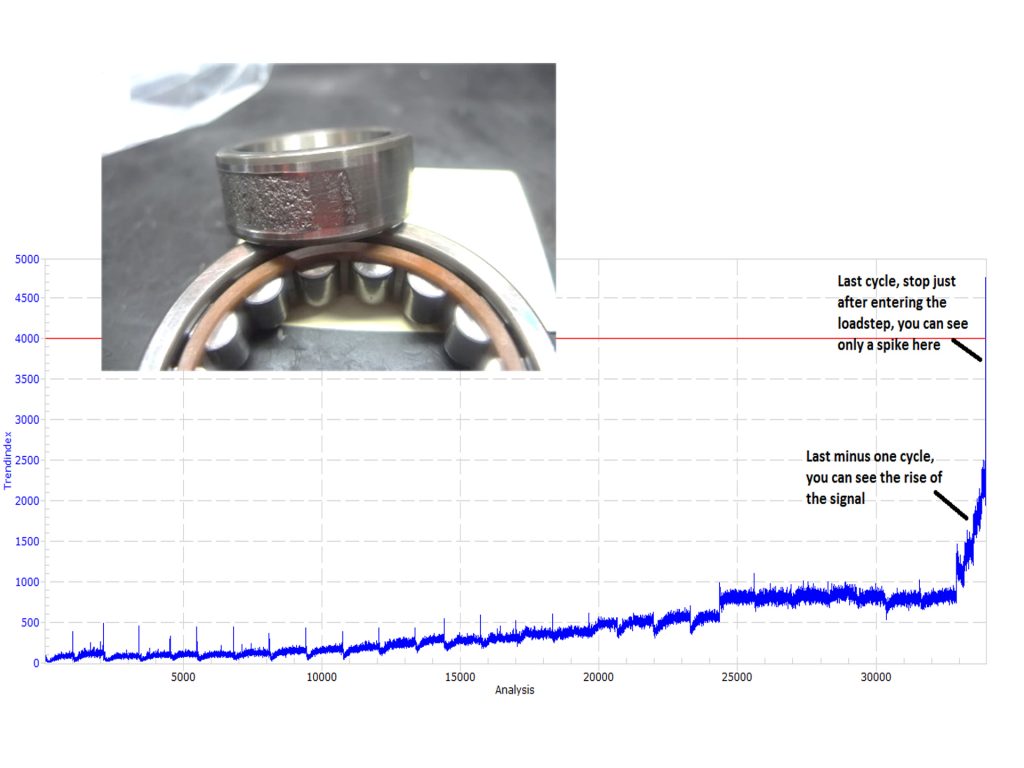

Durability test runs are critical tests. Engines provide the performance of their entire “car life” in just a few weeks. For a high-performance engine, this also means extreme conditions and sometimes racing simulations. The automotive companies in Motor Valley are aware of the importance of these test runs. For many of these companies, the Reilhofer deltaANALYSER is the perfect diagnostic system. The specific hardware and software, combined with personal support, enable companies to protect engines from serious damage on their test benches during durability test runs. In a nutshell overall, it saves time and money.

With the constantly evolving technologies, the deltaANALYSER test departments today help to identify damage at an early stage, which otherwise can lead to dramatic crashes of engines, gears, e-drive units and components. From cracks in pistons, bearing pitting to housing cracks, gear defects and gear wear, as well as a break in the electric motor coil winding, the diagnostic system helps the engineers to stop the test run before a critical failure happens. By measuring the vibration behavior and using the Reilhofer Order Calculator (ROC), it is possible to determine the damage to the affected components in real time over the entire test period.