products

THE QUINTESSENCE.

What is a Global Failure Database?

The Global Failure Database (GFD) is a database in which the quintessential information obtained during testing and/or production is stored as a means of reducing the data volume to a minimum.

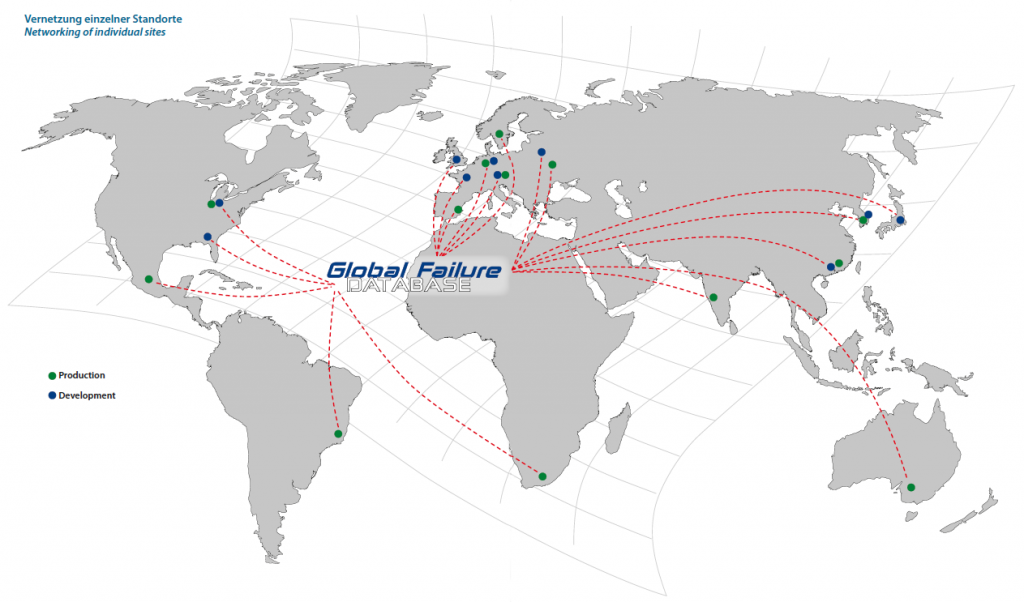

Can several locations enter and access data?

Yes. We enable global use of this standardised archive to ensure that more than one location or department can benefit from this evidence-based knowledge. This is an extremely purposeful development, as most of our customers deploy a large number of NVH systems during development and/or production. Valuable insight, measurement findings and experience are obtained daily at each place of use. The Global Failure Database aggregates this insight and makes it accessible to the people in charge at every facility. By using this database, you connect all departments involved in the product development and life cycle within an active and efficient network.

Which departments benefit?

Production <-> Production

When damage with unknown origins is detected in production, the staff can search the Global Failure Database to identify equivalent cases at other locations. This specimen comparison feature simplifies and accelerates analysis processes. Moreover, a range of statistical methods are available to benchmark the individual production locations with regard to the frequency and causes of faults.

Development -> Production

NVH systems are used in development as well as production, so information obtained on the causes of damage during development can simplify and accelerate analyses performed during production. Entirely along the lines of ‘lessons learned’. When necessary, development departments have quick access to critical test findings collected during production. This process enables faster approvals procedures when time is of the essence.

Production -> Development

Over a thousand insights are acquired in production every day. A variety of fault profiles and component characterisations are available to accommodate the large number of tests and the complexity of production. In turn, development can use this information for pattern recognition.

Development <-> Development

The insight obtained in development across all locations is available at the global level for all future development and analyses.

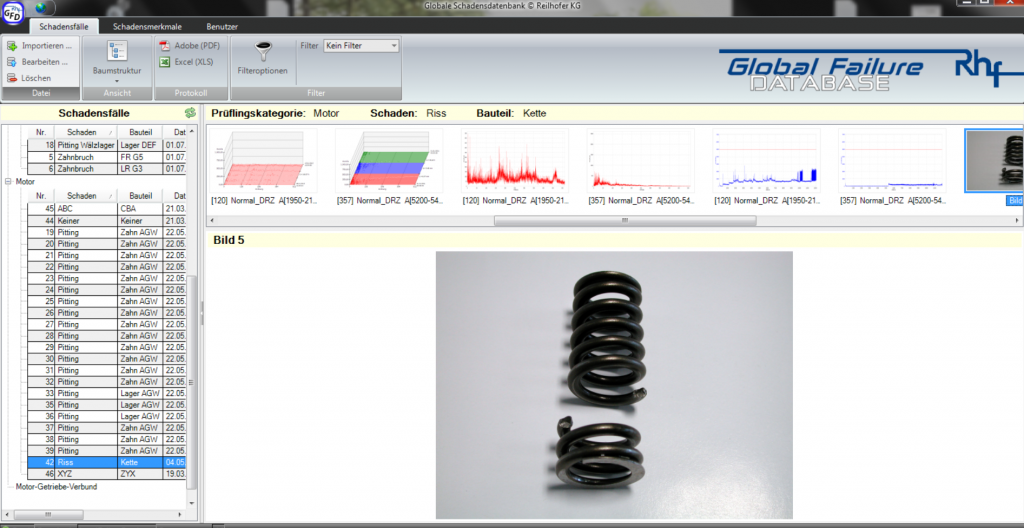

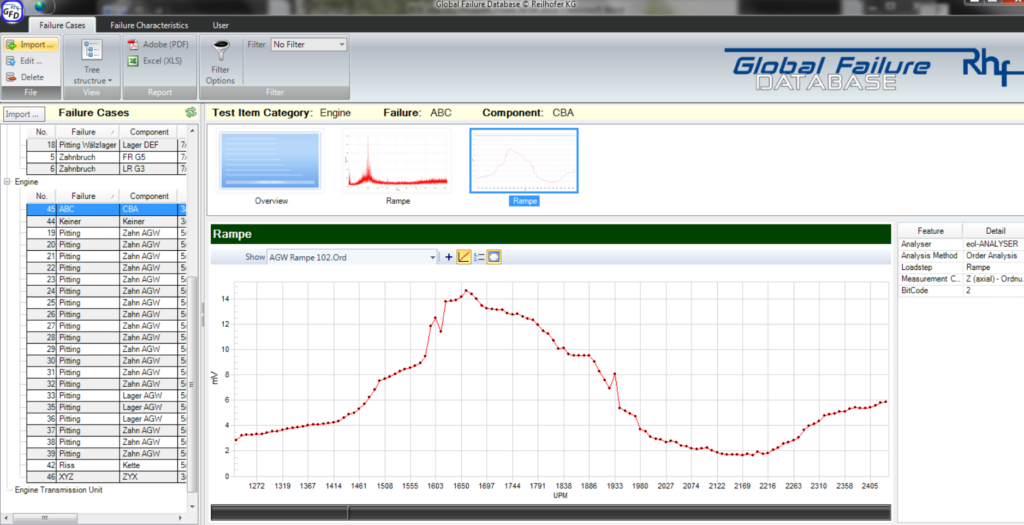

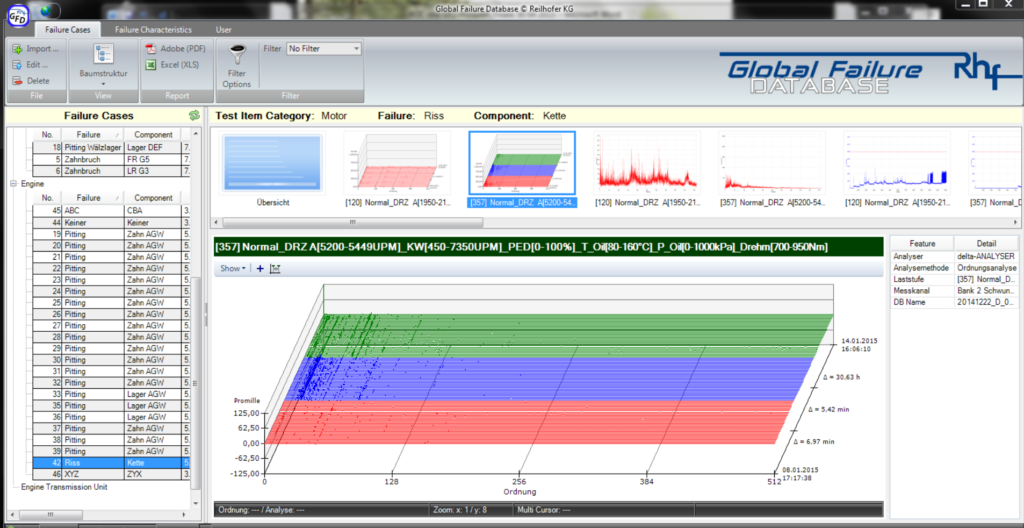

How is the important data transferred from the measurement database to the GFD?

A special plug-in to send reports to the GFD is contained in all of our analysis programs. It is used to add all the required data (spectra, time signals, trends etc.) to an exported file, which is easily imported into the GFD. This means is it no longer necessary to export individual spectra or time signals and then input the information again. Downstream imports of images from the audit or the repair shop are also possible.

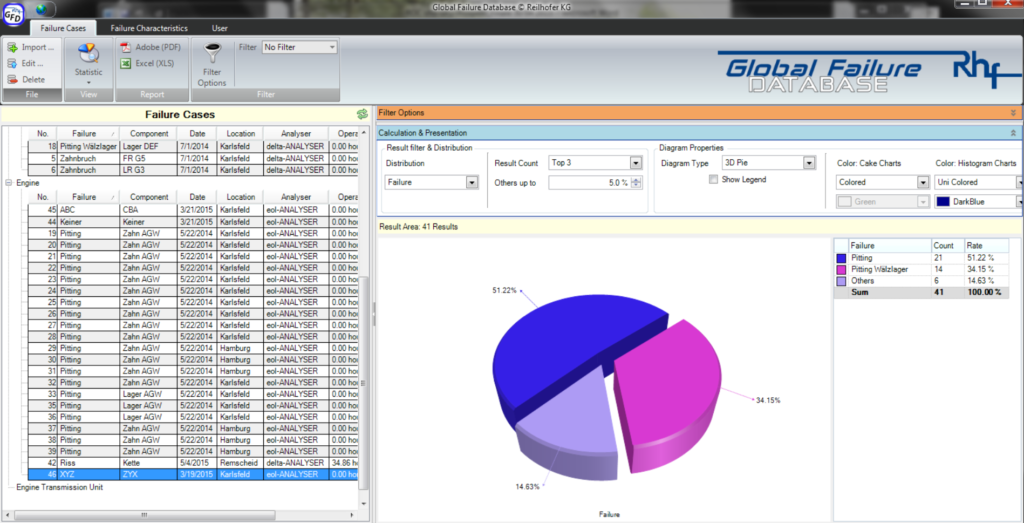

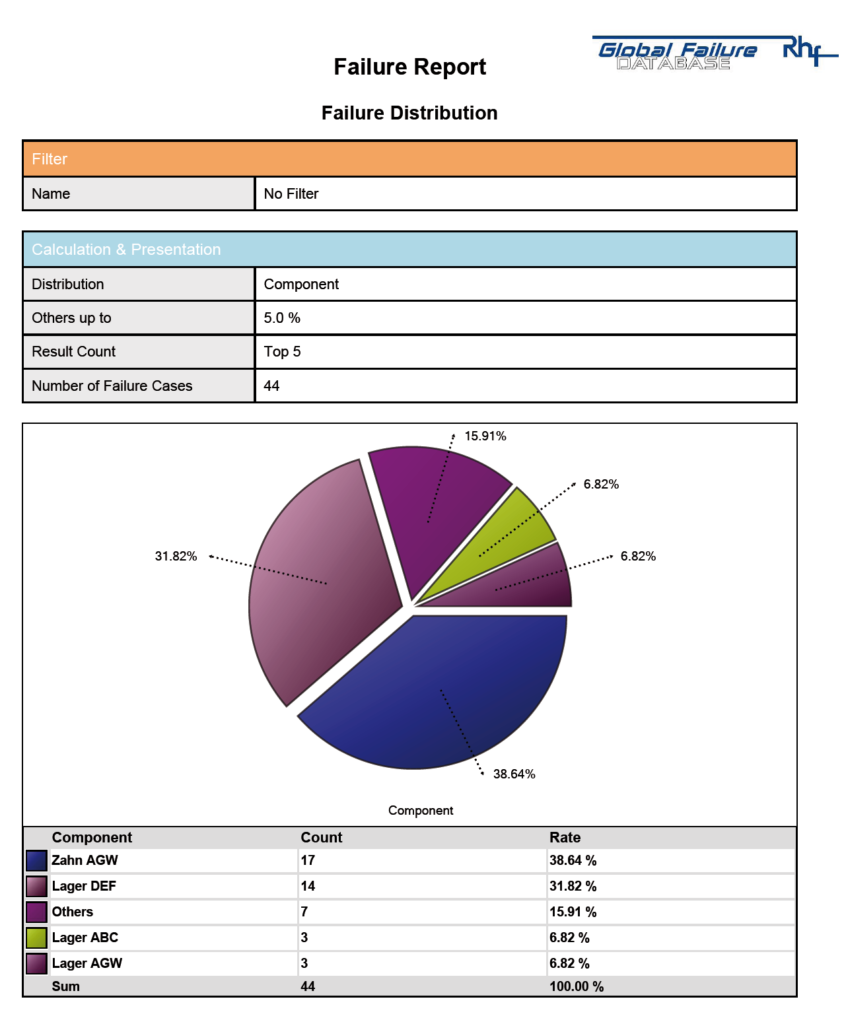

Can you use the data entered to create a report?

Yes. The report generator lets you use all relevant data to create a report, e.g. on damage distribution.

Perfect advice.

Brochures

Download the ROC and GFD brochure to learn more about their capabilities in detail.

Download PDF

Open in your browser

Certified quality: ISO 9001

Assured quality through optimised process management based on ISO 9001:2015 certification. The benefit: perfect product and service quality from day one.

learn more

Standardised export formats